Birla & Circtec: Sustainable Carbonaceous Materials for Rubber & Plastics

The partnership between Birla and Circtec is setting a new standard in producing sustainable carbon black for rubber and plastics using circular, decarbonized feedstocks like pyrolysis oil and rCB.

In its recent press release, Birla Carbon, the world’s largest producer of carbon black, announced a partnership for sustainability with Circtec, an end-of-life tire pyrolysis operator focused on producing renewable fuels and recovered carbon black.

According to the press release:

- Circtec will become the largest producer of Sustainable Carbonaceous Materials

- Birla Carbon to deliver Sustainable Carbonaceous Materials to customers through its extensive product development capabilities

- Partnership to create the single largest source of Sustainable Carbonaceous Materials for the tire, mechanical rubber goods, and plastic industries

Circtec is recognized as a leader in pyrolysis technology and the production of renewable fuels from end-of-life tires. Birla Carbon, the world’s largest producer of carbon black, has signed a long-term supply agreement for Sustainable Carbonaceous Materials with Circtec, creating the industry’s most significant sustainability footprint in the carbon black sector. Birla’s press release highlights that through the company’s technical expertise, customized solutions, and global presence, Birla Carbon will bring this sustainability solution to its customers worldwide. This aligns with Birla Carbon’s leadership position in sustainability and innovation over the past decade.

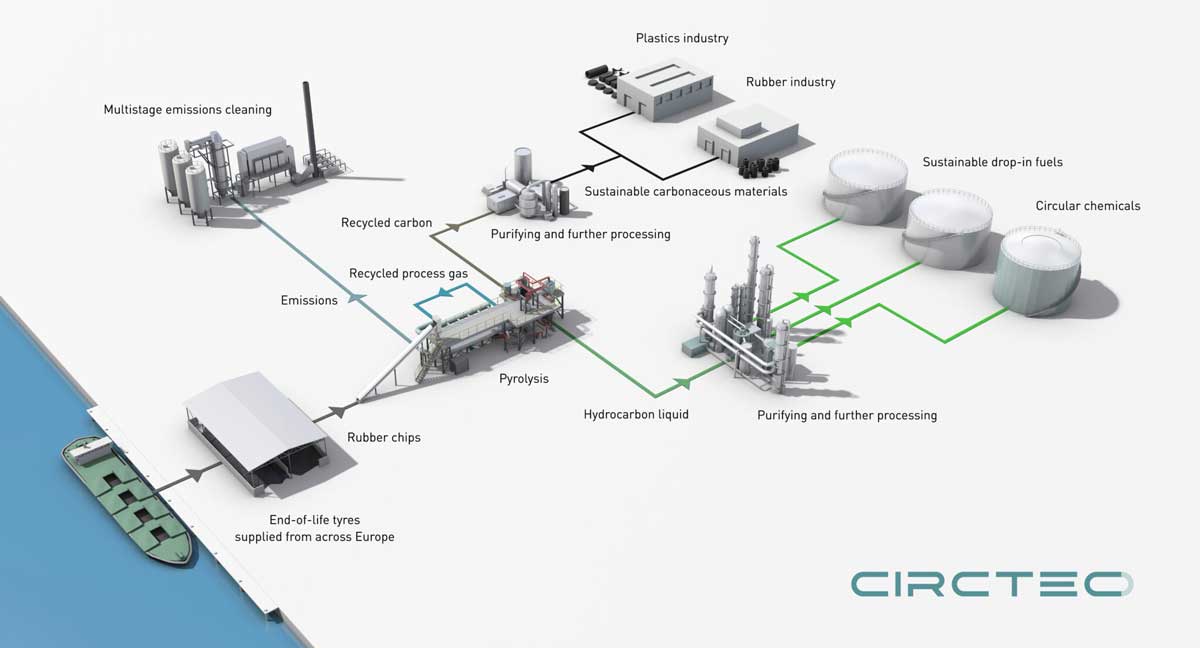

Tire pyrolysis process of Circtec. Together with Birla Carbon, Circtec plans to supply the rubber and plastics industries with Sustainable Carbonaceous Materials. | Graphics by Circtec.

For more than a decade, Circtec has been developing its proprietary production processes to commercial scale, and now, to support this landmark circular economy partnership, Circtec is setting up a flagship production plant in the Netherlands. According to Birla Carbon, Circtec’s pyrolysis plant in the Netherlands will become the most significant, sustainable, and efficient pyrolysis plant in Europe. Circtec’s tire pyrolysis plant is expected to go into production by the end of 2022.

By processing millions of end-of-life tires through the pyrolysis recycling process, the Circtec plant will achieve a total annual production capacity of 73,000 tons of Sustainable Carbonaceous Materials over the next five years. This plant will be the largest single source of Sustainable Carbonaceous Materials and also of product-grade renewable fuels from the end-of-life tire pyrolysis.

Commenting on the association, Dr. Santrupt B. Misra, Chief Executive Officer at Birla Carbon, said:

Our commitment to sustainability over the last decade has enabled Birla Carbon to bring increasingly innovative solutions to our customers. This partnership with Circtec is a significant step towards achieving product circularity in our value chain and bringing our customers’ sustainability aspirations closer to reality. He further added, “Through our collaboration with Circtec, we will become the largest suppliers of Sustainable Carbonaceous Materials in the world, weaving together technology expertise and customized solutions”.

A Life Cycle Assessment (LCA) of Circtec’s process, conducted in accordance with ISO 14040 and ISO 14044, demonstrates that, at full capacity, 228,000 tonnes of direct and indirect CO2 emissions will be eliminated annually when compared to the conventional carbon black process.

Commenting on the partnership with Birla Carbon, Allen Timpany, co-founder and CEO of Circtec, shared, “Our long-term alliance with Birla Carbon is instrumental to our objective to build a leading global business in the low-carbon circular economy.”

Robert Harper, co-founder and Deputy CEO, says:

“We look forward to working on our partnered mission of creating a more circular world, utilizing our leadership in innovation and technology to develop sustainable products from end-of-life tires.”

Pieter Ter Haar, Circtec’s Director of Research and Development, says:

“The combination of Birla Carbon and Circtec gives a leading edge in the development of circular product technology for the carbon black industry.”

Following the news from Circtec and Birla Carbon, Martin von Wolfersdorff, a global carbon black expert, discussed the partnership announcement of the two companies with Robert Harper, co-founder and Deputy CEO of Circtec. The live stream was held on LinkedIn and is available via the link below.

Martin von Wolfersdorff, a global expert in carbon black, discusses the announcement of Birla Carbon’s new Continua brand with Robert Harper, co-founder and Deputy CEO of Circtec, on May 25, 2021. | Interview by Martin von Wolfersdorff.

About Circtec

Circtec is one of the leading innovators of pyrolysis technology and a producer of renewable fuels from end-of-life tires. The Circtec group affiliates have a footprint across 5 countries in Europe, with 2 manufacturing plants and a third under development. In addition to production plants, the group comprises both design and engineering, as well as research and development units. Since 2009, Circtec’s proprietary production technologies have been consistently developed to commercial scale and have supplied several global multinational industrial partners with renewable fuel products over long-term offtake agreements. Circtec is now diversifying to take a leading position in the production of circular economy chemicals. Circtec’s focus is on innovation and technology leadership, scaling sustainability in the chemical, petrochemical, and oil sectors.

To learn more, please proceed to www.circtec.com.

About Birla Carbon

Birla Carbon is one of the leading global suppliers of carbon black. As one of the flagship businesses of the leading Indian multinational conglomerate, the Aditya Birla Group, Birla Carbon provides innovative, sustainable carbon black solutions that enhance the performance of paints and coatings, inks and toners, plastics, adhesives, sealants, textile fibers, mechanical rubber goods, and tires. The company’s footprint spans 12 countries, with 16 manufacturing facilities and two state-of-the-art technology centers in Marietta, USA, and Taloja, India, offering industry-leading innovation. Its Sustainable Operational Excellence (SOE) strategy focuses on employee safety, environmental stewardship, efficient use of carbon sources, and operating in a socially and ethically responsible manner.

For more information, please visit www.birlacarbon.com.

Press release by Birla Carbon.

Carbon Black Is Going Circular — Is Your Supply Chain Ready?

As industry leaders like Birla and Circtec move toward low-emission, circular carbon black, manufacturers must align with sustainable feedstocks to reduce environmental impact and meet ESG goals.

Klean Industries Delivers Circular Carbon Innovation:

✅ Premium-grade recovered carbon black (rCB) from ELTs

✅ Pyrolysis oil as a renewable feedstock for carbonaceous materials

✅ Carbon black upgrading systems for rubber & plastics specs

✅ Lifecycle tracking via the KleanLoop™ blockchain platform

You can return to the main Market News page, or press the Back button on your browser.