Recycled tires pave 600km of rubberized asphalt road in Italy

Italy is revolutionizing road construction using recycled tires to pave 600km of rubberized asphalt roads, marking a significant milestone in sustainable infrastructure development.

This innovative approach reduces waste, enhances road durability, and lowers maintenance costs while cutting carbon emissions associated with traditional asphalt production. As more nations embrace eco-friendly road materials, Italy’s commitment to circular economy principles sets a new benchmark for sustainable infrastructure projects. This market report explores rubberized asphalt’s environmental benefits, economic impact, and future potential as a worldwide scalable solution for road construction.

Ecopneus – Italy’s end-of-life tire management authority responsible for tire collection and recycling – reports that crumb rubber-modified asphalt is growing in the country. In 2020, Italy used 63% more end-of-life tires to pave its roads.

Speaking about the benefits of rubberized asphalt, Ecopneus says it resists potholes, lasts three times longer than traditional asphalt, reduces noise and maintenance costs, and helps utilize a valuable commodity—tire-derived crumb rubber—that otherwise would often end up in landfills.

According to Ecopneus data, in 2020, about 600 km of Italy’s roads were built using rubber-modified asphalt from recycled tires. For illustration, this distance could cover the journey from Rome to Milan.

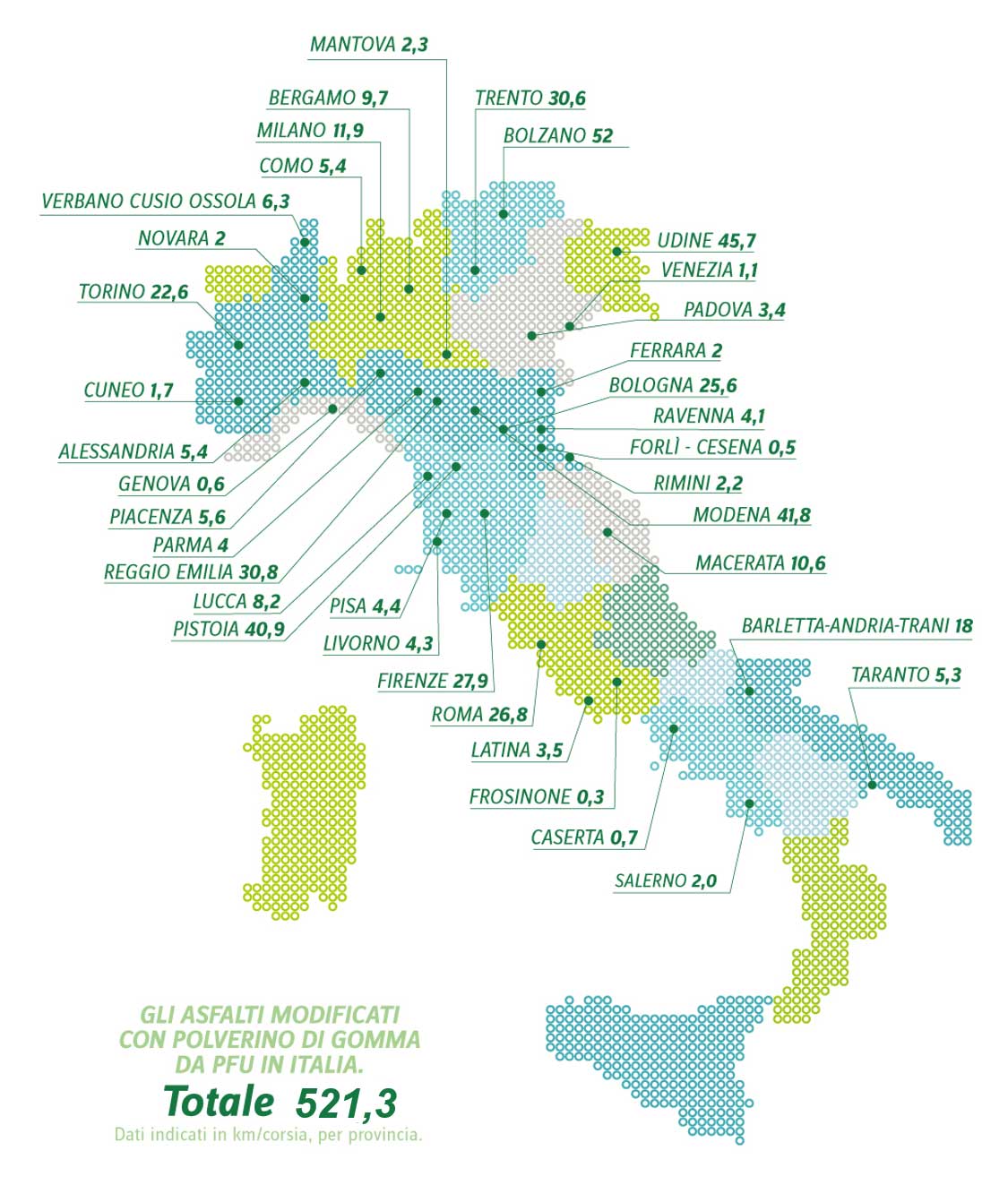

Ecopneus pinpoints that asphalt modified with recycled tire rubber represents an innovative and advantageous solution, practiced for over 60 years worldwide. In Italy, technology has started finding more and more use: in fact, it has gone from just over 100 km in 2010 to 600 km at the end of 2020, with an increase of 63% compared to 2019. Ecopneus says that 42 provinces of Italy have chosen to rely on this valid technology: Emilia-Romagna, Tuscany, Piedmont, and Trentino Alto-Adige. Today, these regions have the most significant experience of using rubberized asphalt from recycled end-of-life tires.

Mid-2020 progress with paving rubberized asphalt roads from end-of-life tires in Italy | Graphics by Ecopneus.

This is a positive trend and confirmation of the sector’s maturity, especially compared to last year, when the difficulties and restrictions related to the COVID-19 pandemic recorded a general contraction in most sectors.

Asphalt modified with recycled rubber currently represents one of the most interesting solutions for public administrations and authorities managing Italian roads. It allows them to invest better economic resources in road infrastructure while reducing inconvenience for drivers and travelers. The construction activity’s environmental impact and road maintenance costs are also very beneficial, as described above.

“The results achieved encourage us to continue using this material,” – said the General Manager of Ecopneus, Giovanni Corbetta. “At Ecopneus, we worked hard over the years to spread greater knowledge on this valid application of recycled rubber; we have activated and supported several scientific studies and initiatives, such as the EU co-funded Life Nereide project. For 2021, we hope for an ever wider diffusion of this technology, thanks to the entry into force of the new End of Waste decree, which will provide important support to increase the quality of materials recycled from ELTs. Many important national companies are also increasingly attentive to this technology.”

Using recycled rubber powder from end-of-life tires makes it possible to create asphalt capable of combining high-level mechanical performance with positive effects for the community regarding noise reduction and environmental sustainability, thanks to rubber from recycled tires. Precisely for these reasons, the initiative in the Pavese area received funding from Cassa Depositi e Prestiti, which recognized this solution’s technological and environmental value.

Press release by Ecopneus.

Why Klean Industries is Leading the Future of Sustainable Infrastructure

As Italy sets a new standard for rubberized asphalt roads, global industries must adopt innovative, circular economy solutions for infrastructure development. Klean Industries provides cutting-edge tire recycling and asphalt modification technologies, turning end-of-life tires into high-performance, eco-friendly road materials.

Why Klean Industries?

✅ Advanced Tire Recycling for Sustainable Road Construction – Converting waste tires into durable rubber-modified asphalt.

✅ Cost-Effective & Eco-Friendly Pavement Solutions – Enhancing road longevity while reducing carbon footprints.

✅ Turnkey Circular Economy Systems – Supporting governments and infrastructure developers with scalable solutions.

✅ Trusted by Industry Leaders – Helping municipalities and construction firms transition to green road building.

Looking to Develop Sustainable Roads Using Recycled Tires?

Contact Klean Industries to explore high-performance, low-carbon road paving solutions.

You can return to the main Market News page, or press the Back button on your browser.