Sustainable Carbon Black Produced from End-of-life Tire Pyrolysis Oil

A breakthrough in pyrolysis oil technology is enabling the sustainable production of carbon black from end-of-life tires.

Introduction

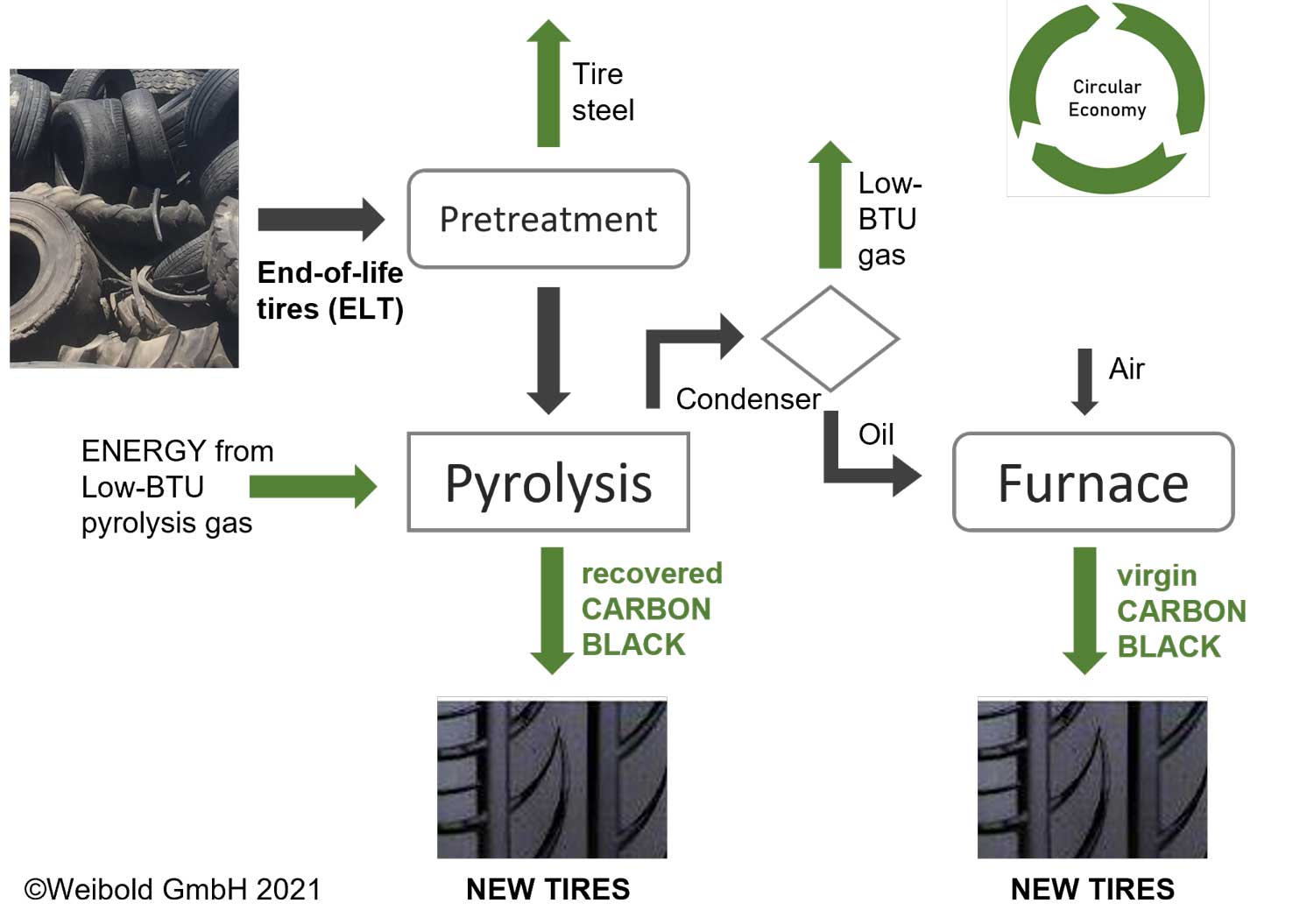

State-of-the-art pyrolysis processes are an efficient, viable, and sustainable approach for the valorisation of end-of-life tires (ELT) into oil, gas, and recovered Carbon Black (rCB). They are thus an essential step towards transitioning to a low-carbon, more sustainable, resource-efficient, and circular economy, in line with the European Union’s Green Deal and the United Nations’ Sustainable Development Goals.

Carbon Black (CB) is an irreplaceable component in tires. The current feedstocks used in CB production are fossil fuel-based resources, which are susceptible to volatile oil prices and associated high CO2 emissions. According to the ORION Sustainability Report 2020 and Notch Consulting, the global demand for Carbon Black in 2020 was estimated to be 11.9 million tons, consuming over 30 million tons of fossil fuel. Meanwhile, the GHG emissions by the carbon black industry as a whole have been 23.8 million tons. Notch Consulting’s forecast for carbon black demand in 2029 is estimated at 18.7 million tons, following the expected increase in tire production. Using the same intensity rate, GHG emissions associated with the Carbon Black industry would increase by 13.6 million tons to 37.4 million tons.

The EU-Taxonomy explicitly cites industrial (virgin) Carbon Black production as making a substantial contribution to climate change. To contribute to the climate protection goal, emissions from the production of Carbon Black must therefore be reduced.

It is demonstrated that transitioning from current fossil-based feedstocks to alternative feedstocks derived from the pyrolysis of end-of-life tires is a viable long-term pathway to ensure the sustainable production of CB at reduced costs. A crucial step towards a circular economy.

Revival of a decades-old concept

The first conceptual proposals for substituting fossil carbon black feedstocks (CBFS) with pyrolysis oil from end-of-life tires were published by WÓJTOWICZ and SERIO in 1996. Subsequently, the U.S. Environmental Protection Agency co-funded a series of tests by Advanced Fuel Research Inc., the results of which were published in 2004.

Despite the experimental limitations (low temperature and laminar flow), the data for Carbon Black produced from end-of-life tire-derived pyrolysis oil (TDO) were promising and generally fell within the range of values characteristic of ASTM carbon blacks. [WÓJTOWICZ et al., 2004]

In 2020, under the coordination of the tire manufacturer MICHELIN, the EU-HORIZON2020-funded € 16 million project “BlackCycle” began rolling out a circular concept for the tire industry. The BlackCycle project aims to create, develop, and optimize a full value chain, from ELT feedstock to high-tech secondary raw materials (SRMs), with no waste of resources at any part of the chain and specific attention to environmental impact. In particular, the Carbon Black, a material representing ~20% of tire composition, will be fully obtained from oils extracted from waste tires through the pyrolysis process. [EU CORDIS Fact Sheet]

Opportunities and challenges

Judging by the abundance of publications on tire pyrolysis in general and recovered Carbon Black in particular, the substitution of fossil-based CBFS by TDOs seems to have been overlooked until the start of the BlackCycle project.

Thanks to Okeoye and colleagues from the University of Western Australia, a literature review has been available on this topic since 2020, which gives a good overview of the great opportunities in terms of the transition to circular economy and the (minor) challenges of it.

Sustainable Carbon Black produced from end-of-life tire pyrolysis oil. | Graphics by Claus Lamer, Weibold.

Besides being a valuable feedstock for various chemical components, TDO presents an attractive source of renewable energy. It has come a long way in being considered a potential substitute for crude oil-derived products or for use in blends with them. The raw waste tire-derived pyrolysis liquids are the most economically and energetically attractive products. However, their fuel application is challenging because of several properties: their distillation characteristics, a wide boiling point range, flash point, cetane number, density, PAH content, sulphur, chlorine content, etc. and a distinct lack of clarity to what constitutes action toward TDO quality gate limits to be supplied to refineries for further processing. These challenges are circumvented if TDOs are used as raw material for CB, and all problematic substances that would be released when used as fuel are destroyed by the high process temperatures (up to 1900 ° C) or bound in the manufactured product. Thus, upgrading raw tire-derived oils (TDO) with chemical and physical techniques, although associated with a cost, is appropriate to enhance the TDO properties further.

TDO contains over 100 identified compounds, dominated by aromatics, aliphatics, heteroatoms, and polar fractions. [Kaminsky et al., 2009; Banar et al., 2012 cited in OKOYE et al., 2020].

The high aromatic content of TDO is a crucial parameter in selecting it as a suitable CB feedstock. Polycyclic aromatic hydrocarbons (PAHs) are a necessary precursor for carbon nucleus (CB) formation, and a high aromatic content improves the CB production yields. [OKOYE et al., 2020]

According to Wójtowicz and colleagues, the sulfur content of TDO does not affect the CB production yield, surface area, and particle size (although the sulfur content in any CB feedstock is always associated with emission and environmental protection requirements).

To produce CB with the furnace method, a high carbon-to-hydrogen ratio and high aromaticity of the feedstock are important. A suitable CB feedstock has an H/C ratio in the range of 7.10 to 13.30. Several pyrolysis studies have shown that TDO has an H/C ratio in the range of 7.30 to 12.90, like conventional CB feedstocks. TDO as a CBFS is additionally attractive because of its high aromatic hydrocarbon content. TDO exhibits consistently higher aromaticity (up to 51 wt.%) compared to the “ideal CB feedstock” coal tar (~18 wt.%). [OKOYE et al., 2020].

Conclusion

The carbon-to-hydrogen (C/H), sulfur, and aromatic contents of pyrolysis oil derived from end-of-life tires (TDO) are comparable to those of fossil-based fuel feedstocks used in commercial CB manufacturing. The performance of TDO in terms of feedstock to CB conversion yield and other industrial properties is not only similar to that produced with a fossil fuel feedstock but also consistent with ASTM standards for CB, even though it has been relatively overlooked. [OKOYE et al., 2020]

The utilisation of TDO in CB manufacturing can, therefore, offer a sustainable approach to provide a cleaner route to the production of cost-effective Carbon Black.

The BlackCycle project coordinated by a leading tire manufacturer (Michelin) in which authoritative entities such as ORION Engineered Carbon GmbH, PYRUM Innovations AG, CIENTIFICAS, ALIAPUR, SISENER INGENIEROS SL, and others also participated, will likely result in a comprehensive understanding of the combustion chemistry of this sustainable feedstock, which is essential in predicting the performance and control of CB formation. This can pave the way for the practical application of TDO as a cleaner alternative feedstock for CB production on a commercial scale.

Literature

- Chiemeka Onyeka Okoye, Isabelle Jones, Mingming Zhu, Zhezi Zhang, Dongke Zhang, Manufacturing of carbon black from spent tyre pyrolysis oil: A literature review, Journal of Cleaner Production, Volume 279, 2021, 123336, ISSN 0959-6526 (document available here).

- Wójtowicz Marek, Bassilakis Rosemary, Serio Michael. (2004). CARBON BLACK DERIVED FROM WASTE TIRE PYROLYSIS OIL—proceedings of the Carbon 2004 Conference, Brown University, Providence, RI.

- Wójtowicz Marek, Serio Michael. (1996). Pyrolysis of Scrap Tires: Can it be profitable? Chemtech October 1996 (document viewed on October 10, 2021).

You can return to the main Market News page, or press the Back button on your browser.