-

Canada: GVRD

Sustainable Development Goals

Project Status:

Completed | Operating Since 1985

Organizations Involved:

City of Vancouver, Greater Vancouver Regional District (GVRD), BC Ministry of Environment, City of Burnaby, Fraser Health Authority, Babcock Wilcox, Alstom, BC Hydro, NORPAC, Veolia ES, Covanta

Services: Consulting, Feasibility Study, Due Diligence, CSR Education Plan

The Challenge:

Vancouver is Canada's 3rd largest metropolitan region, with an estimated population base of 2.5 million people. It operates the 3rd largest Port in North America and is a significant infrastructure owner as it manages approximately $25 billion of capital assets encompassing facilities, parks, streets, and underground infrastructure. Since 2011, the City has adopted a service-based capital planning framework to drive accountability, increase transparency, and enhance a holistic, city-wide approach to long-term capital investment decision-making.

It is estimated that the Greater Vancouver Regional District (GVRD) and its residents, businesses, and institutions generated about 1,247,500 tonnes of garbage in 2021-2022. The GVRD has improved its recycling rate in the last few years, from about 40 percent in 1995 to over 60 percent in 2018. Concrete, yard, and food waste (organics) are some of the most recycled materials in the metro region.

Key Facts & Figures

The Solution:

Sustainability has played a significant role in managing municipal solid waste within the GVRD. This region is one of the first in Canada to consider creating energy from waste using an integrated solid waste management system. Since its opening in 1988, Metro Vancouver’s Waste-to-Energy Facility (WTEF) has played an essential role in the region’s solid waste management system.

Metro Vancouver owns the energy from the waste facility, which, when built, was initially operated and maintained by a subsidiary of Veolia ES; the facility is now operated and maintained by Covanta Burnaby Renewable Energy Inc. The facility ensures that garbage is managed environmentally and generates renewable and valuable energy sources such as steam and electricity. The Waste-to-Energy Facility (WTEF) is located in the commercial and industrial areas of south Burnaby. It receives waste from Burnaby, New Westminster, and the North Shore of Vancouver and is responsible for the environmentally safe disposal of over 20 percent of the region’s waste.

In 2003, the GVRD installed a turbo generator that uses steam to produce electricity and then sells it to BC Hydro. In 2006, a $7 million upgrade was completed to increase the heat recovered from the waste and the amount of electricity produced. The revenue from steam and electrical sales offset the operational costs of the solid waste management system. Strict environmental monitoring confirms that the WTEF is one of the cleanest facilities of its kind. The Solid Waste Association of North America (SWANA) recognizes it as one of the best facilities on the continent. In 2003, the Association of Professional Engineers and Geoscientists of B.C. (APEGBC) presented its first Sustainability Award to the GVRD, partly for installing the turbo generator.

In 2018, Metro Vancouver introduced technological improvements to increase metal recovery at the Waste-to-Energy Facility. An eddy current separator was installed to separate non-ferrous metals such as copper and aluminum from bottom ash, and a second magnetic separator increased the recovery of ferrous metals.

The Outcome:

The site was initially established in 1985 to utilize steam through sales to a paper recycler, and the site's central location was selected because it minimized the distance of hauling waste, resulting in further benefits for the facility. This was designed with future potential in mind for eco-efficiency. Commercial operation started in 1988, using a state-of-the-art combustion and air pollution control system. Over 50% of the facility equipment is dedicated to air pollution control. This waste-to-energy facility has three processing lines, each processing about 11 tonnes of garbage every hour. Since its start-up, it has processed more than 5 million tonnes of municipal solid waste.

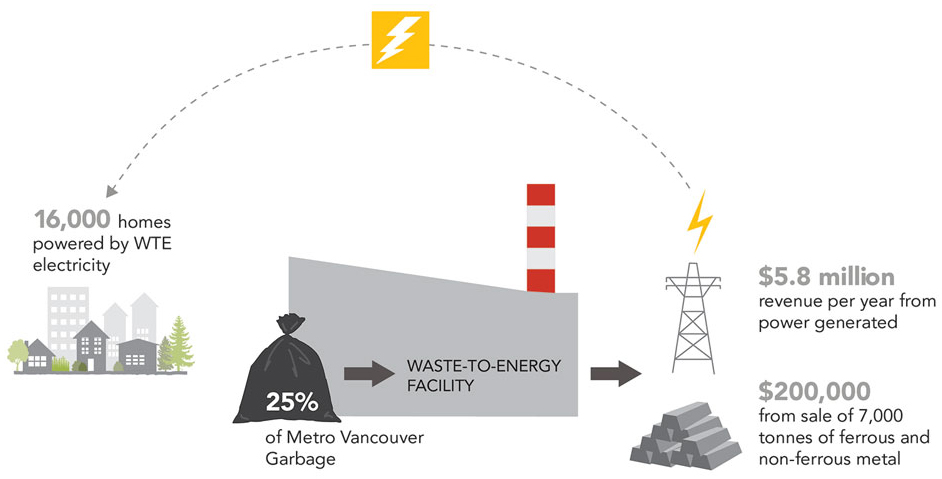

Throughout its 30+ years in service, each year, the WTEF turns, on average, 250,000 tonnes of garbage and trash into 900,000 tonnes of steam and 132 GWh of electricity, providing both economic and environmental benefits to the region. A portion of this steam was initially sold to North Pacific Paper Company (NORPAC), a paper recycling facility, helping eliminate the use of fossil fuels. Air emissions produced from the facility are a small percentage of the total air emissions in Metro Vancouver. The facility operates under continuous air emissions monitoring within all regulated limits.

The electricity sold to BC Hydro is enough to power 16,000 homes and recovers about 7,000 tonnes of metal annually. The Solid Waste Association of North America (SWANA) recognizes it as one of the best facilities on the continent. The benefits of a Waste-to-Energy plant like the Burnaby facility are that it can be located in densely populated metropolitan areas as a highly responsible local disposal solution for waste that cannot be recycled. Metro Vancouver annually earns approximately $8 million from the sale of electricity and $300,000 from the sale of recycled metal to a company that produces reinforcing steel.

Strict control over combustion conditions, such as temperature and airflow, minimizes the amount of emissions released. State-of-the-art environmental protection technology treats air emissions continuously, monitoring them and regulating them under provincial legislation. Monthly reports are submitted to the Provincial Ministry of Environment, the City of Burnaby, and the Fraser Health Authority. Independent stack tests are performed on each processing line three times a year to test for acid gases, total hydrocarbons, metals, and particulate matter. The Lower Fraser Valley Air Quality Monitoring Network continuously monitors the ambient air environment at 30 sites throughout the Lower Mainland. No measurable impact has ever been found from the energy-from-waste facility.

The BC Minister of Environment approves the facility through an Operational Certificate, which sets requirements related to its operation, including emissions limits, monitoring, reporting, and publication. Strict environmental tracking confirms that the WTE facility is one of the cleanest facilities of its kind.

The WTEF has zero liquid discharges (excluding washrooms) to the sewer system. This means reduced impacts on the environment by minimizing water use and lowering demand on the sewer system. The WTEF is certified by the International Standard Organization (ISO) 14001. This is an international environmental management protocol to ensure regulatory compliance, ongoing monitoring, and continual improvements. Additional key attributes are:

Summary of the 2018 operation costs:

Awarded for Operational Excellence in Waste to Energy:

If you would like to learn more about this project, please get in touch with us now >> GO.

We support our client’s through our quoting and project development by providing a wealth of information and specifications about Klean Industries systems and technologies.

©2025 All Rights Reserved. Terms of Use