-

Italy: IET

Sustainable Development Goals

Project Status:

Completed | Operations 2012 - 2020

Organizations Involved:

Klean Industries, Italiana Energetica Tire, Ecopneus, Nippon Steel & Sumitomo Corporation, Nippon Steel & Sumikin Engineering, Steinmüller (Fisia) Babcock Environment Gmbh, Techint Engineering & Construction, Sojitz

Services:

Feasibility Studies, Due Diligence, Component Supply, Packaged Solutions

The Challenge:

In 2012, Klean Industries (“Klean”) was engaged to conduct a Detailed Feasibility Study (“DFS”) for a new company called Italiana Energetica Tire (“IET”) based in Milan. IET was established to promote innovative technological systems for treating end-of-life tires. The company intended to enhance these systems by developing its flagship facility in Italy, which is aimed at responsibly recovering sustainable resources from tires, specifically biogenic tire pyrolysis oil (TPO) and recovered carbon black (rCB). The management team at IET consisted of a group of young entrepreneurs with substantial industrial experience in innovation and management, financially supported by the founders of Wally Yachts.

Italy faces a significant environmental challenge concerning the management of end-of-life tires (ELTs). In 2022, nearly 500,000 metric tons of ELTs were collected for recovery. Despite these efforts, a substantial portion remains in landfills or is incinerated, leading to environmental pollution and resource wastage. Traditional disposal methods contribute to soil and water contamination, while incineration releases greenhouse gases, worsening climate change. The challenge is to find a sustainable and efficient solution to transform this waste into valuable resources while minimizing environmental impact.

Since 2006, a European Union directive has prohibited sending End-of-Life Tires (ELTs) to landfills, recognizing the quality and value of recycled rubber for compulsory recovery. However, until 2011, Italy lacked a national stewardship system for managing the complete collection and recovery of used tires, rendering the country in dire need of a system for monitoring and tracking ELTs. This system became operational on September 7, 2011 (DM 82/2011). Ecopneus functions within this legal framework, tracking, collecting, and sending ELTs to recovery facilities across Italy. Ecopneus’s ELT collection rates correspond to the market share represented by the partner companies within the stewardship program, accounting for about 60% of national production, equivalent to an average of 200,000 tonnes per year.

The Solution:

In September 2012, Klean collaborated with IET in an initiative called “Request for Proposals (RFP) for Investments in Italy for Processing Plants that Recover End-of-Life Tires,” promoted by Ecopneus. The RFP aimed to coordinate the tracing, collection, treatment, and final disposal of ELTs, identifying new technologies and plant solutions that could optimize the recovery chain for scrap tires. It also stipulated that owners of the selected initiatives would receive ELT supply contracts essential for their plants. IET was awarded a multi-year feedstock agreement to supply all of its annual ELT needs in the category of “pyrolysis” (Reference 3 of the call for proposals mentioned above).

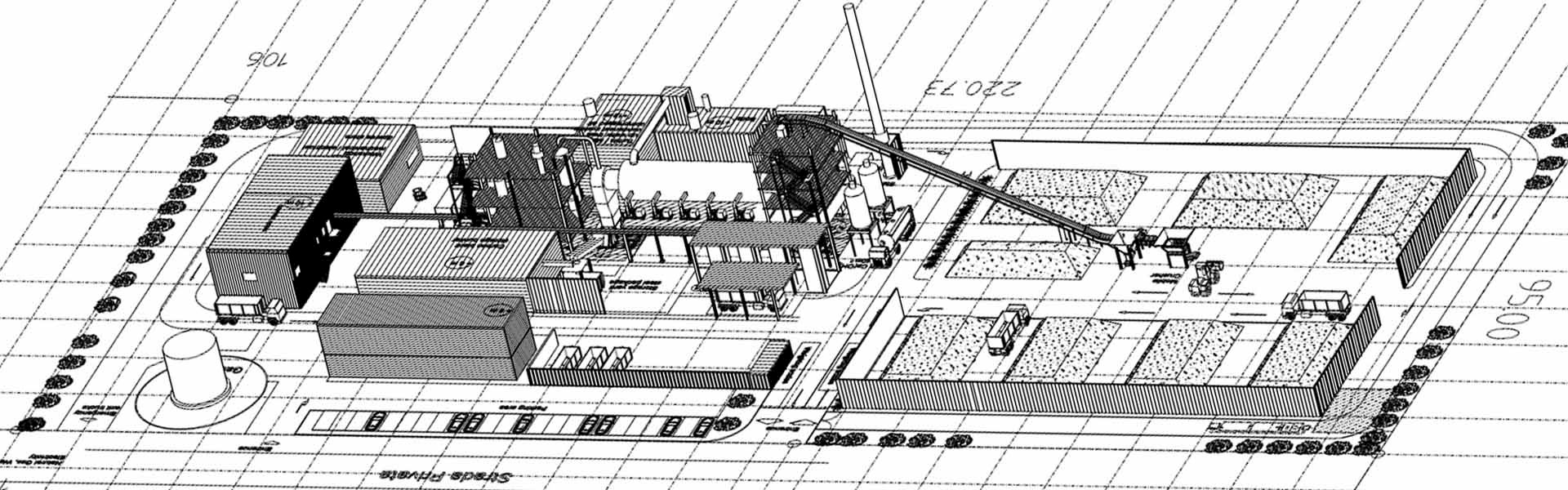

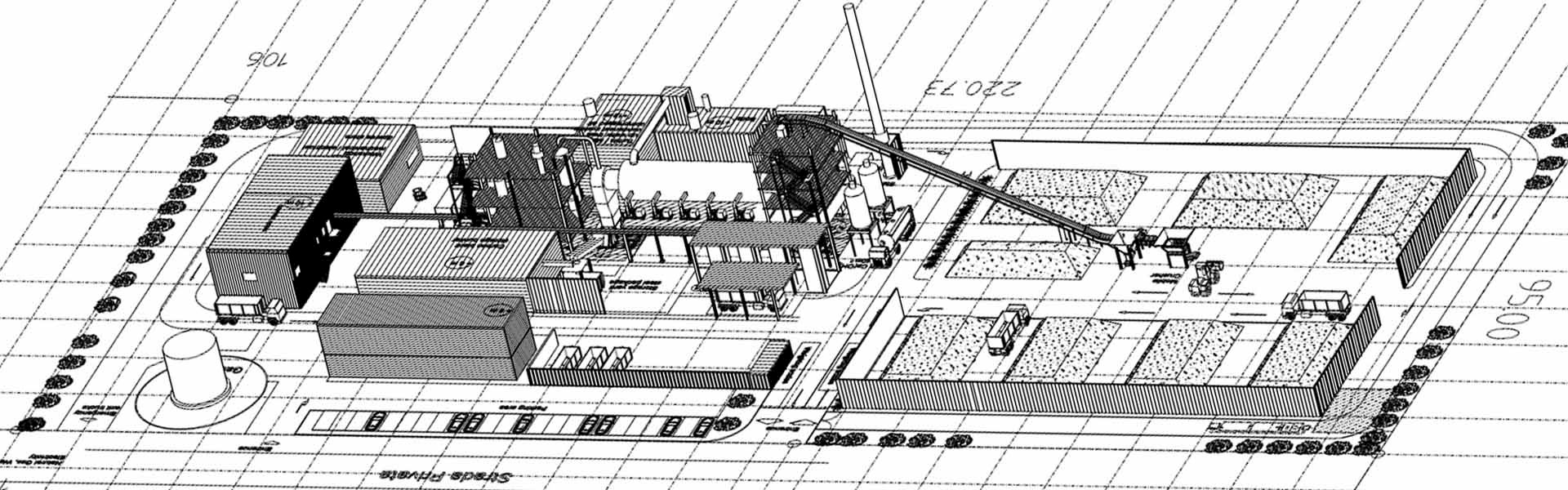

The plant was designed to treat 100 metric tons of end-of-life tires per day (33,000 metric tons per year) at maximum production capacity, which translates to a treatment capacity that can absorb about 6% of Italy's yearly production of waste tires.

Tire pyrolysis is an innovative, eco-friendly solution to Italy's ELT crisis. This advanced recycling process thermally decomposes tires in an oxygen-free environment, breaking them down into highly valuable byproducts:

Italy can significantly reduce its reliance on landfill disposal and incineration by implementing tire pyrolysis. This will promote a circular economy in which valuable materials are reintegrated into industrial production cycles. This sustainable approach aligns with global carbon neutrality goals and supports the European Green Deal initiatives.

The Outcome:

Klean Industries was responsible for bringing all the technical parties together, except for the local Italian consulting and supporting engineering firms. In May 2013, Klean Industries completed its engagement with IET, outlining several key, project-specific issues that needed to be resolved despite the project's potential as a flagship for end-of-life tire processing in Italy. Due to underlying challenges that had yet to be resolved, Klean chose to abandon its involvement in the IET project as a joint venture partner and equipment supplier. In conclusion, if IET had addressed these key issues outlined in the DFS, the project could have reached a Financial Investment Decision (FID). That is the power of doing a Detailed Feasibility Study to avoid costly project mistakes.

Adopting tire pyrolysis technology in Italy has already shown considerable environmental and economic benefits. Resource recovery organizations like Ecopneus recovered over 230,000 tonnes of ELTs in 2022, ensuring these materials were repurposed instead of discarded. Converting ELTs into high-value commodities significantly reduces the need for landfill disposal and incineration.

If you would like to learn more about this project, please get in touch with us now >> GO.

We support our client’s through our quoting and project development by providing a wealth of information and specifications about Klean Industries systems and technologies.

©2025 All Rights Reserved. Terms of Use